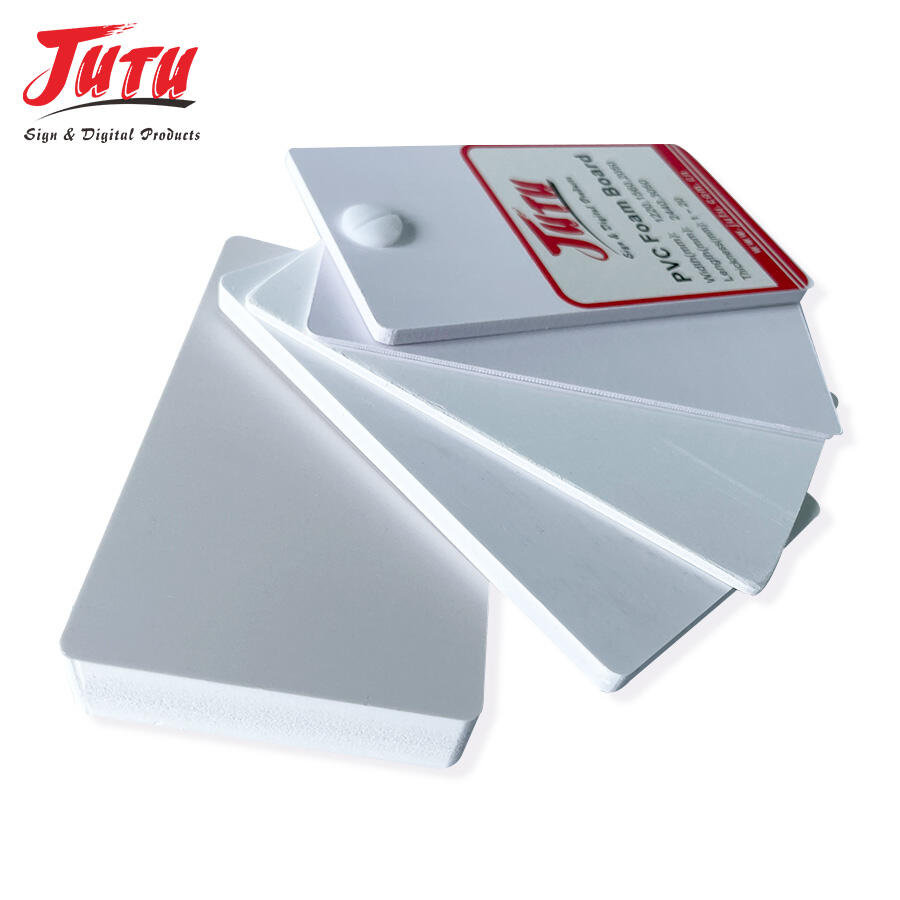

wpc foam sheet

WPC foam sheet represents a revolutionary advancement in composite material technology, combining the natural benefits of wood fibers with the durability and versatility of plastic polymers in a lightweight, foamed structure. This innovative material emerges from the fusion of wood particles, thermoplastic resins, and specialized foaming agents, creating a product that delivers exceptional performance across multiple applications. The manufacturing process involves precisely controlled temperature and pressure conditions, allowing the wpc foam sheet to achieve optimal cellular structure while maintaining structural integrity. The primary functions of wpc foam sheet extend far beyond traditional building materials, offering superior insulation properties, moisture resistance, and dimensional stability that conventional wood products cannot match. Technological features include advanced cellular architecture that reduces weight by up to 40% compared to solid WPC boards while preserving strength characteristics. The foam structure incorporates closed-cell design principles, preventing water absorption and enhancing thermal insulation capabilities. Surface treatments and co-extrusion processes enable manufacturers to customize texture, color, and protective layers according to specific application requirements. Applications span residential and commercial construction sectors, including exterior siding, interior wall panels, ceiling systems, and decorative architectural elements. Marine and automotive industries increasingly utilize wpc foam sheet for non-structural components requiring lightweight, weather-resistant materials. The versatility extends to furniture manufacturing, signage production, and specialized industrial applications where traditional materials fall short of performance expectations. Processing capabilities allow for standard woodworking techniques including cutting, drilling, routing, and fastening, making installation straightforward for contractors and DIY enthusiasts alike.