Recent Innovations in Acrylic Board Manufacturing

Advanced Coatings and Surface Treatments

You see advanced coatings and surface treatments transforming acrylic board manufacturing. These innovations enhance the durability and visual appeal of acrylic boards. Manufacturers now apply scratch-resistant coatings to protect surfaces from wear and tear. Anti-glare finishes improve visibility, making these boards ideal for displays and signage. UV-resistant coatings shield acrylic boards from sunlight, preventing discoloration and extending their lifespan. These treatments ensure that the boards maintain their quality in demanding environments.

Surface treatments also focus on aesthetics. High-gloss finishes create a sleek, polished look, while matte finishes offer a subtle, modern appearance. Textured surfaces add depth and character, catering to creative industries. These advancements allow you to choose acrylic boards that meet both functional and design requirements.

Laser-Cutting and Precision Technologies

Laser-cutting technology has revolutionized acrylic board manufacturing. This method delivers precise cuts with smooth edges, eliminating the need for additional finishing. You can achieve intricate designs and complex shapes with ease. Laser-cutting ensures accuracy, making it suitable for applications like architectural models, decorative panels, and custom signage.

Precision technologies also play a key role in improving production efficiency. Automated systems reduce errors and speed up the manufacturing process. CNC (Computer Numerical Control) machines enable consistent results, even for large-scale projects. These technologies allow manufacturers to meet high standards while maintaining cost-effectiveness.

Nano-Coatings and Smart Materials

Nano-coatings represent a cutting-edge innovation in acrylic board manufacturing. These ultra-thin layers enhance the performance of acrylic boards in unique ways. Anti-fog coatings prevent condensation, making them useful for bathroom mirrors and vehicle windows. Self-cleaning coatings repel dirt and water, reducing maintenance efforts. Anti-microbial coatings inhibit bacterial growth, ensuring hygiene in medical and food-related applications.

Smart materials are another exciting development. These materials respond to environmental changes, such as temperature or light. For example, photochromic acrylic boards darken under sunlight, providing shade and reducing heat. Thermochromic boards change color with temperature shifts, adding an interactive element to designs. These advancements open new possibilities for functional and creative uses.

Enhanced Casting and Extrusion Techniques

Advanced casting and extrusion techniques have revolutionized acrylic board production, enabling higher precision, quality, and versatility. Casting produces clear, strong boards by pouring liquid acrylic into molds, ideal for thick sheets and custom shapes. Extrusion melts pellets into sheets, offering quicker production and uniform thickness, suitable for signage and displays. Recent improvements have enhanced board uniformity and smoothness. Manufacturers now use hybrid methods that combine casting's clarity with extrusion's efficiency, meeting modern industry demands affordably and reliably.

Advanced Processing Technologies (e.g., thermal bending, sandblasting)

Advanced technologies improve acrylic boards' functionality and design. Thermal bending shapes acrylic into curves or angles while preserving strength, useful for furniture and architectural elements. Sandblasting adds texture, creating frosted finishes for privacy or decoration, ideal for partitions and signage. Laser engraving and polishing expand creative options, with engraving adding detailed patterns and polishing restoring clarity. These processes enhance manufacturing versatility, meeting functional and aesthetic needs.

Sustainable Practices in Acrylic Board Manufacturing

Recycling and Reuse Initiatives

Recycling and reuse have become essential in acrylic board manufacturing. You can see manufacturers adopting processes to minimize waste and purpose materials. Scrap acrylic from production lines often gets collected, melted, and reformed into new sheets. This approach reduces the need for virgin materials and lowers production costs. By recycling, you help conserve resources and reduce the environmental footprint of manufacturing.

Reuse initiatives also play a significant role. Many companies encourage customers to return used acrylic boards for refurbishment. These boards undergo cleaning, polishing, or reshaping to extend their lifespan. This practice not only benefits the environment but also provides cost-effective solutions for consumers. Recycling and reuse ensure that acrylic boards remain a sustainable choice for various industries.

Green Manufacturing Methods

Green manufacturing methods focus on reducing energy consumption and emissions during production. You might notice manufacturers switching to renewable energy sources, such as solar or wind power, to run their facilities. These energy-efficient practices lower carbon emissions and contribute to a cleaner environment.

Water conservation is another priority. Advanced systems recycle water used in cooling and cleaning processes, ensuring minimal wastage. Some manufacturers also adopt non-toxic chemicals for cleaning and coating, which reduces harm to workers and ecosystems. By embracing green methods, you support a manufacturing process that prioritizes environmental health without compromising product quality.

Biodegradable and Eco-Friendly Alternatives

Biodegradable and eco-friendly alternatives are transforming the acrylic board industry. Researchers are developing materials that break down naturally over time, reducing long-term waste. These alternatives use bio-based polymers derived from renewable sources like plants. You can expect these materials to perform similarly to traditional acrylic while being more environmentally friendly.

Eco-friendly coatings and additives further enhance sustainability. For example, water-based coatings replace solvent-based ones, reducing harmful emissions. Manufacturers also experiment with natural dyes and pigments to create vibrant, non-toxic colors. These innovations allow you to choose products that align with your commitment to sustainability. Biodegradable and eco-friendly options ensure that acrylic board manufacturing evolves to meet the demands of a greener future.

Sustainability in Bulletproof Acrylic Sheet Production

Using recycled acrylic waste reduces the need for new materials and waste in landfills. Opting for recycled products supports a circular economy and lowers the environmental impact of manufacturing. Energy-efficient methods, including renewable energy sources, and advanced technologies minimize energy waste and greenhouse gas emissions. Sustainable, non-toxic coatings replace harmful solvent-based options, aligning with environmental goals. Lightweight designs reduce material use, production costs, and environmental impact, while improving transportation efficiency. These sustainable practices reflect a commitment to responsible manufacturing, ensuring a balance of safety, performance, and environmental stewardship.

Customization and Personalization Trends

3D Printing in Acrylic Board Production

3D printing has introduced a new dimension to acrylic board production. This technology allows you to create intricate designs and complex structures with unmatched precision. By layering material, 3D printing enables the production of customized acrylic boards tailored to specific needs. You can use this method to produce prototypes, decorative pieces, or functional components for various industries.

The flexibility of 3D printing makes it ideal for small-scale projects or unique designs. You can experiment with shapes, patterns, and dimensions that traditional methods cannot achieve. This approach reduces material waste, as it uses only the exact amount needed for each project. With 3D printing, you gain the ability to bring creative ideas to life while maintaining efficiency and sustainability.

Color Mixing and Texturing Techniques

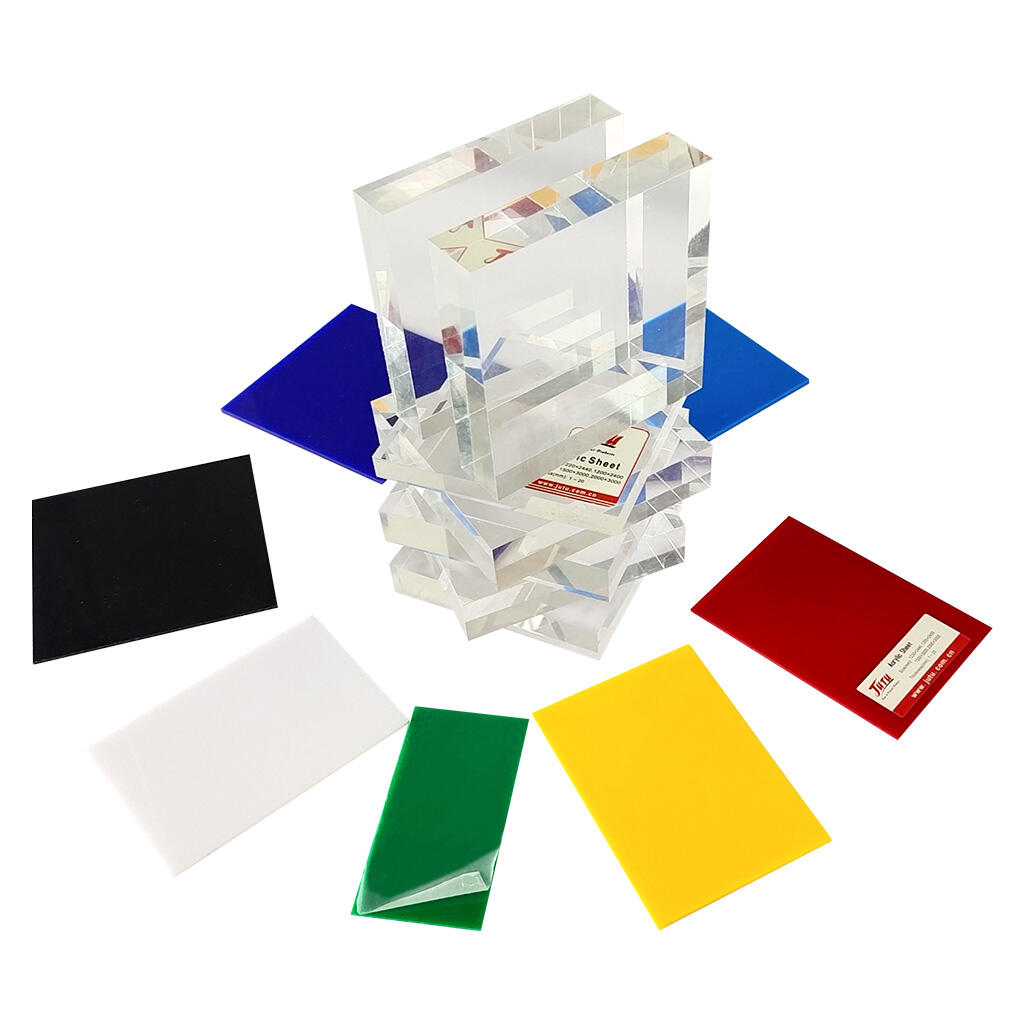

Color mixing and texturing techniques give you the freedom to personalize acrylic boards to match your vision. Manufacturers now offer a wide range of color options, from vibrant hues to subtle tones. You can choose solid colors, gradients, or even transparent shades to suit your project. Custom color mixing ensures that the final product aligns perfectly with your design requirements.

Texturing adds another layer of customization. Techniques like embossing, engraving, and sandblasting create unique surface patterns. You can opt for smooth finishes, rough textures, or intricate designs that enhance the visual appeal of the acrylic board. These techniques also improve functionality. For example, textured surfaces can reduce glare or provide better grip in certain applications. By combining color and texture, you can achieve a truly personalized product.

Tailored Solutions for Niche Markets

Tailored solutions cater to the specific needs of niche markets. Acrylic board manufacturing has evolved to address the demands of industries like healthcare, retail, and interior design. You can request custom sizes, shapes, and features that meet the unique requirements of your field. For instance, medical facilities often need anti-microbial acrylic boards for hygiene purposes, while retail stores may require branded displays with custom logos.

Small businesses and individual creators also benefit from tailored solutions. You can order acrylic boards in limited quantities without compromising quality. This flexibility allows you to pursue creative projects or specialized applications. Manufacturers work closely with you to ensure that the final product aligns with your goals. Tailored solutions empower you to explore new possibilities and stand out in your industry.

Challenges in Small Volume Custom Projects

Mass production optimization makes it difficult to handle specialized small orders. High production costs and longer setup times for small batches increase unit prices and can lead to less cost-effectiveness compared to bulk orders. Lead times are longer for small volume orders due to prioritization of large orders by manufacturers, and specialized designs or features further extend production timelines. Material waste is a concern as small quantities often result in unused materials, impacting costs and sustainability. Quality control is challenging for custom projects requiring high precision and attention to detail, especially with intricate designs or unique specifications. Manufacturers may adopt flexible production methods, such as modular systems or 3D printing, to reduce costs and waste. Collaborating with specialized manufacturers can also improve outcomes for custom projects. Understanding these challenges allows for informed decision-making and finding suitable solutions.

Future Outlook for Acrylic Board Manufacturing

Smart acrylic boards are an advanced type of acrylic board that adapts to environmental changes. They include photochromic boards that adjust transparency with light exposure, suitable for energy-efficient windows or dynamic displays, and thermochromic boards that change color with temperature, useful for temperature-sensitive applications. Interactive smart acrylic boards feature touch-sensitive surfaces for kiosks or control panels, and LED lighting systems for visual effects in advertising or interior design. Ongoing research on self-healing acrylic boards promises to extend product lifespan and reduce maintenance. Smart acrylic boards are set to play a key role in future design and functionality.

Advancements in Automation and AI

Automation and AI are revolutionizing Acrylic Board Manufacturing by streamlining processes and enhancing efficiency. Automated systems and robots ensure consistent quality and precision in tasks like cutting, shaping, and polishing. AI's machine learning algorithms analyze data to optimize production schedules, minimize waste, and reduce costs, leading to faster delivery and more affordable products. Predictive maintenance using sensors prevents downtime and maintains product quality. As these technologies advance, they promise greater efficiency and innovation in the industry.

Trends in Overseas Production and Market Dynamics

Regions with skilled labor and advanced facilities offer manufacturers efficient scaling opportunities and a variety of acrylic boards for various uses. Global supply chains, sourcing materials from multiple countries, ensure steady product supply but also pose challenges like shipping delays and price fluctuations. Competition from overseas production drives innovation and quality improvements, offering better products and services. Eco-friendly practices by overseas manufacturers align with sustainability concerns, allowing you to choose environmentally responsible products. Trade policies and tariffs affect the cost and availability of acrylic boards, so staying informed helps in planning and making informed choices.

Acrylic Board Manufacturing continues to evolve with groundbreaking innovations that redefine quality and efficiency. You see advancements like smart materials, precision technologies, and sustainable practices shaping the industry’s future. These developments not only enhance functionality but also address environmental concerns. Customization trends empower you to create unique solutions tailored to your needs. Emerging markets and smart acrylic boards promise exciting opportunities for growth and innovation. By staying informed, you can leverage these advancements to achieve your goals while contributing to a more sustainable and dynamic industry.