celuka board

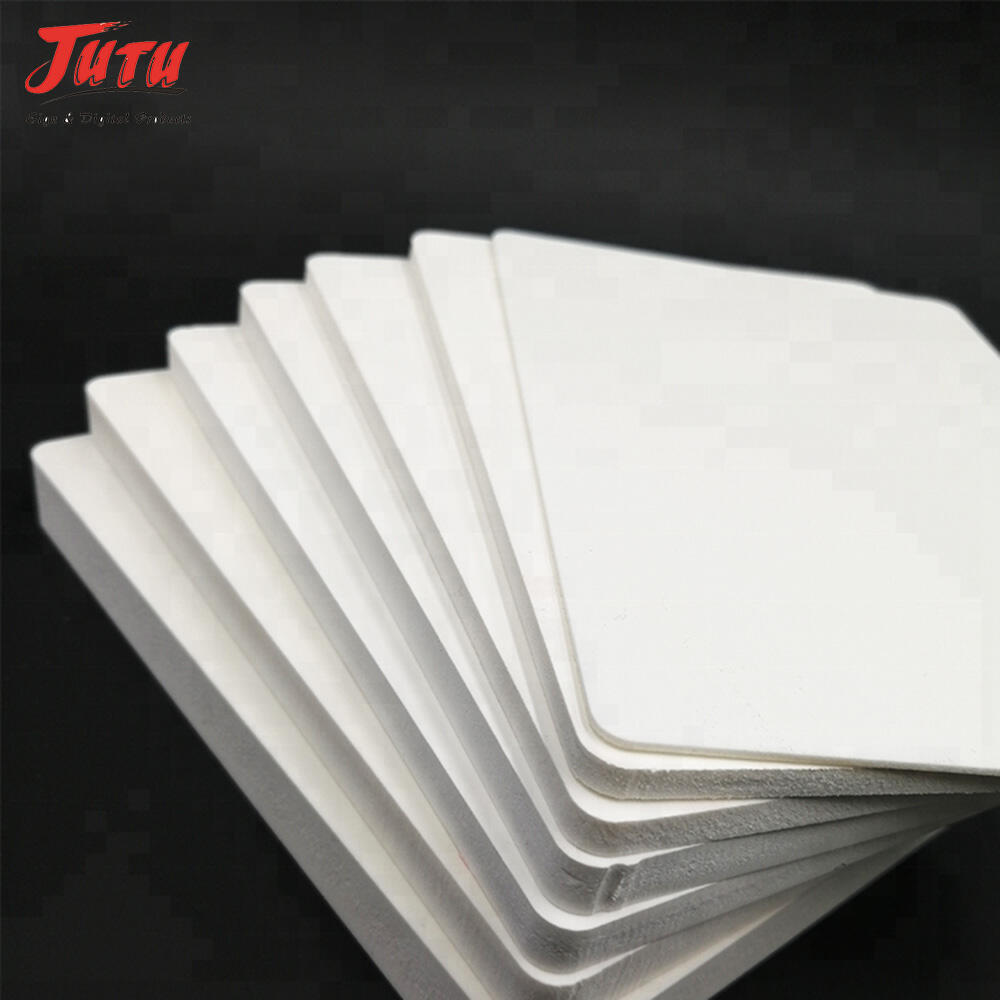

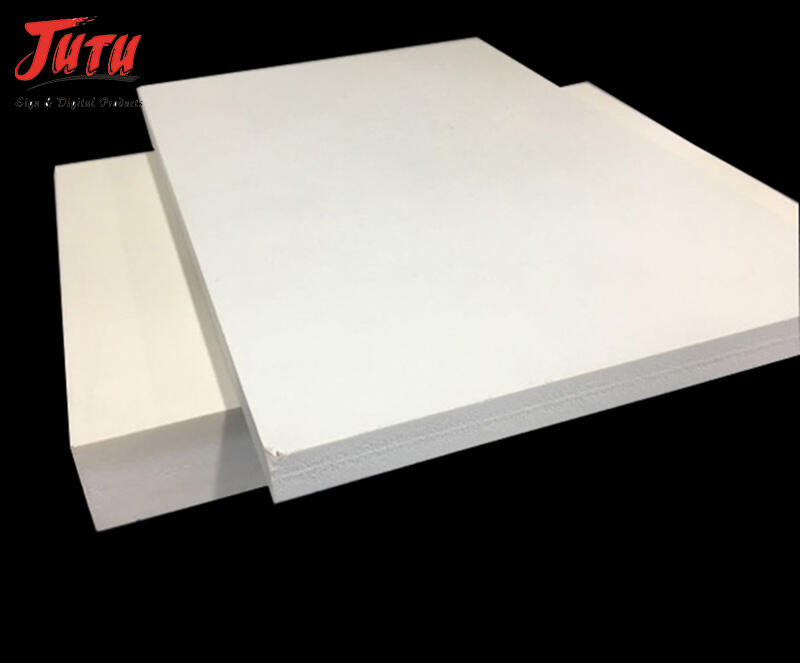

The celuka board represents a revolutionary advancement in foam board technology, designed to meet the demanding requirements of modern construction, signage, and manufacturing industries. This innovative composite material combines the lightweight properties of traditional foam boards with enhanced durability and superior performance characteristics. The celuka board features a unique cellular structure that provides exceptional strength-to-weight ratios, making it an ideal choice for applications requiring both structural integrity and ease of handling. The board's construction involves advanced polymer chemistry that creates a closed-cell foam core, surrounded by smooth, dense outer skins that resist moisture, chemicals, and environmental degradation. This multi-layer design ensures consistent performance across various temperature ranges and humidity conditions. The celuka board's main functions include structural support, insulation, and surface finishing in diverse applications. Its technological features encompass excellent machinability, allowing for precise cutting, routing, and shaping using standard woodworking tools. The material exhibits superior flatness and dimensional stability, crucial for precision applications. The celuka board demonstrates remarkable versatility in applications spanning architectural modeling, exhibition displays, furniture manufacturing, automotive components, and marine construction. Its closed-cell structure prevents water absorption, making it suitable for outdoor installations and humid environments. The board's chemical resistance extends its usability in industrial settings where exposure to various substances is common. Manufacturing processes benefit from the celuka board's consistent density distribution and predictable behavior during fabrication. The material's surface accepts various finishes including paints, laminates, and vinyl graphics, expanding its aesthetic possibilities. Quality control measures ensure each celuka board meets stringent standards for thickness tolerance, density uniformity, and surface quality, providing manufacturers with reliable material properties for consistent production outcomes.