Flexibilidade Excepcional de Fabricação e Liberdade de Design

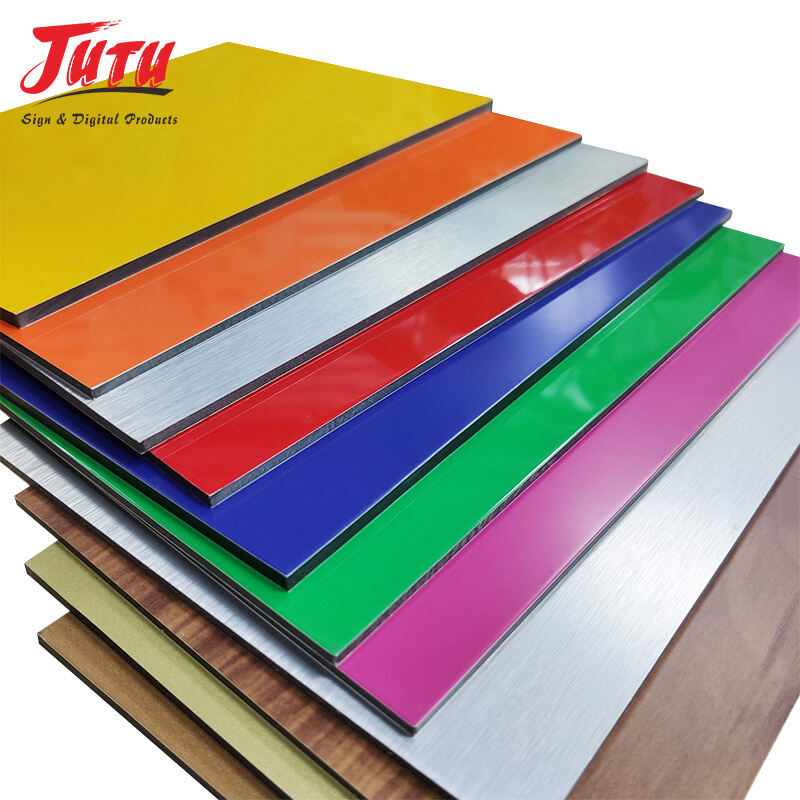

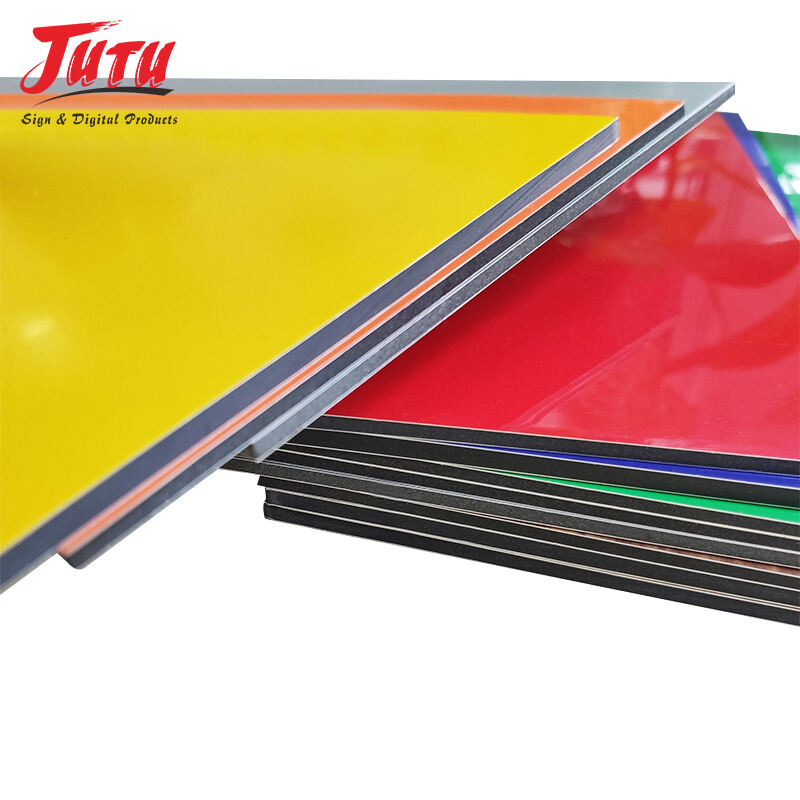

A chapa composta de alumínio de 3 mm oferece uma flexibilidade de fabricação sem igual, permitindo que arquitetos e designers concretizem formas geométricas complexas e conceitos estéticos inovadores sem limitações materiais. A espessura ideal de 3 mm permite operações precisas de dobragem, curvatura e conformação utilizando equipamentos padrão de metalurgia, criando oportunidades para fachadas curvas, revestimentos de colunas e elementos arquitetônicos tridimensionais que seriam difíceis ou impossíveis com materiais mais espessos. A densidade constante do núcleo e a aderência das camadas de alumínio garantem que as formas fabricadas mantenham sua forma e integridade estrutural ao longo do tempo, eliminando preocupações com deformações ou falhas nas linhas de dobra. Fabricantes profissionais podem obter raios apertados e arestas nítidas preservando o acabamento superficial liso característico de instalações de qualidade. O material responde de forma previsível a diversas técnicas de conformação, incluindo dobramento em freio, conformação por rolos e operações de moldagem personalizadas, permitindo estimativas precisas de custos e cronogramas de projeto. Operações de corte produzem bordas limpas, sem rebarbas ou deslaminação, quando empregadas técnicas e ferramentas adequadas, facilitando juntas precisas e instalações com aparência profissional. A construção leve simplifica o manuseio durante a fabricação e reduz os custos de transporte para componentes pré-formados, tornando projetos complexos mais viáveis economicamente. Os métodos de união incluem fixadores mecânicos, adesivos estruturais e sistemas de montagem especializados que acomodam a movimentação térmica mantendo a integridade da vedação contra intempéries. O material aceita diversos tratamentos e texturas superficiais durante a fabricação, incluindo acabamentos escovados, padrões em relevo e reproduções fotográficas, ampliando as possibilidades de design além das cores sólidas. A capacidade de impressão digital permite aplicar permanentemente gráficos personalizados, fotografias arquitetônicas e elementos de marca à superfície, criando efeitos visuais únicos impossíveis com materiais tradicionais. A estabilidade dimensional dos componentes fabricados elimina a necessidade de ajustes no campo e garante encaixe adequado durante a instalação, reduzindo custos com mão de obra e atrasos no projeto. Chapas compostas de alumínio de qualidade mantêm tolerâncias consistentes de espessura, possibilitando fabricação de precisão e eliminando desperdícios de material associados às variações de espessura presentes em produtos alternativos.